ABOUT KINGS

Ningbo Kings Industrial Co., Ltd.

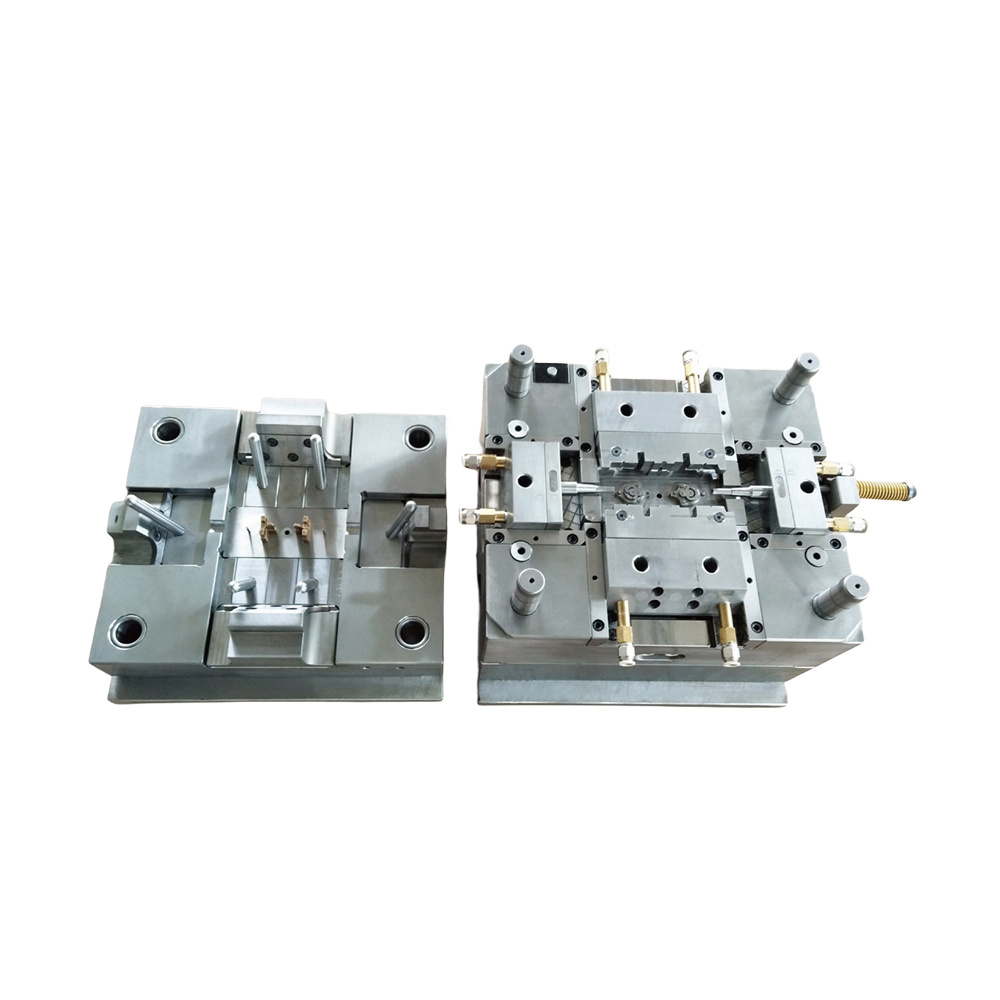

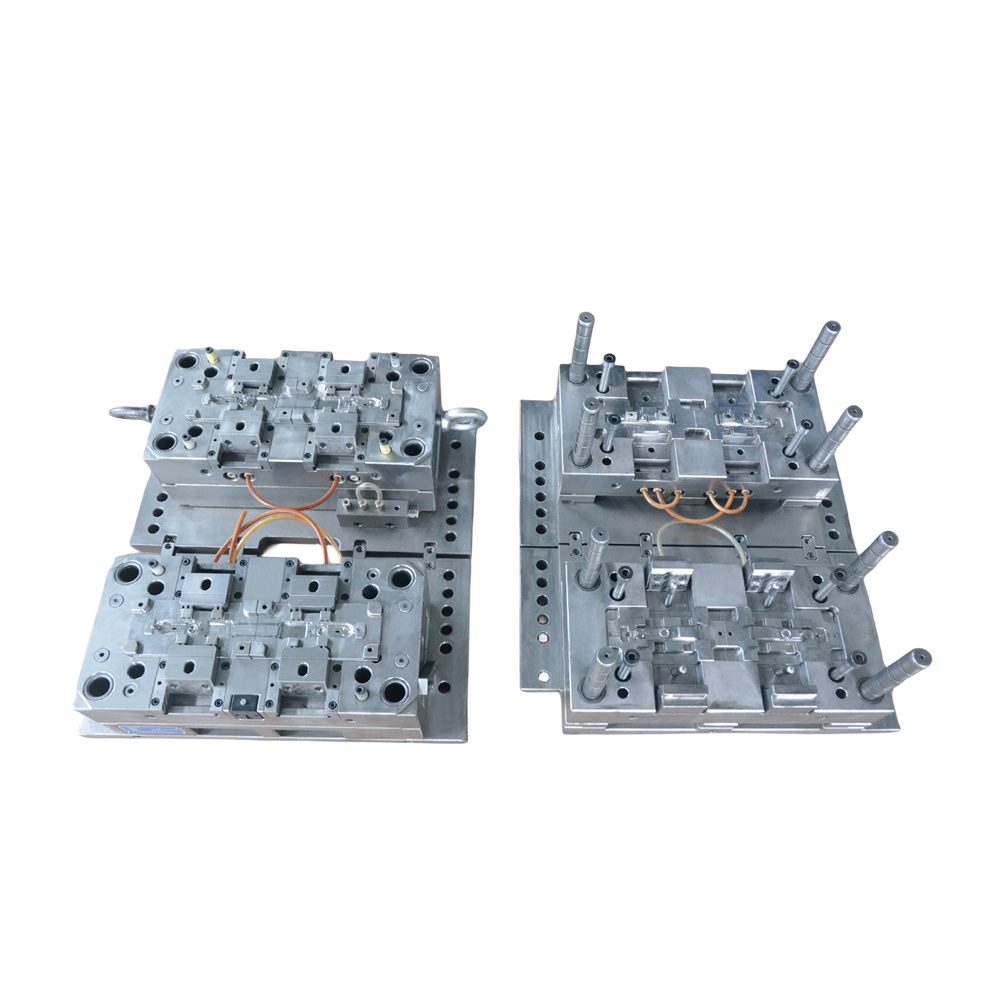

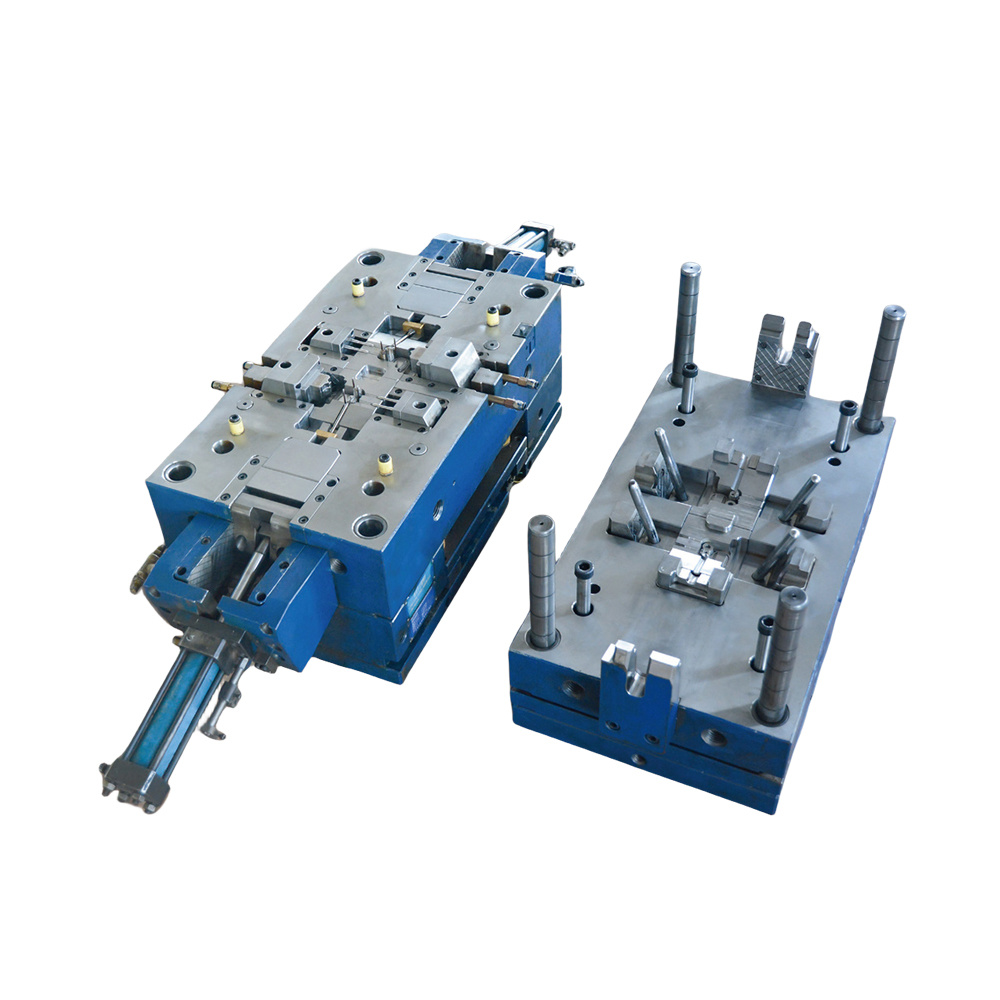

Founded in 1994, the company is a high-precision mold design, research and development, manufacturing as the core technology, a collection of mold manufacturing, injection molding, metal stamping, product manufacturing as one of the high-tech enterprises. The company's products cover high-precision mold manufacturing, electrical switch boxes, electrical accessories three series of more than a thousand kinds, mainly sold to Europe and the United States and other places, the current independent brand EES products to open up the domestic low-voltage building electrical market.

Learn more

Company established (year)

Number of Employees (person)

Building area (M²)

Products

Kings Industries

Always committed to seeking better technology and products for partners

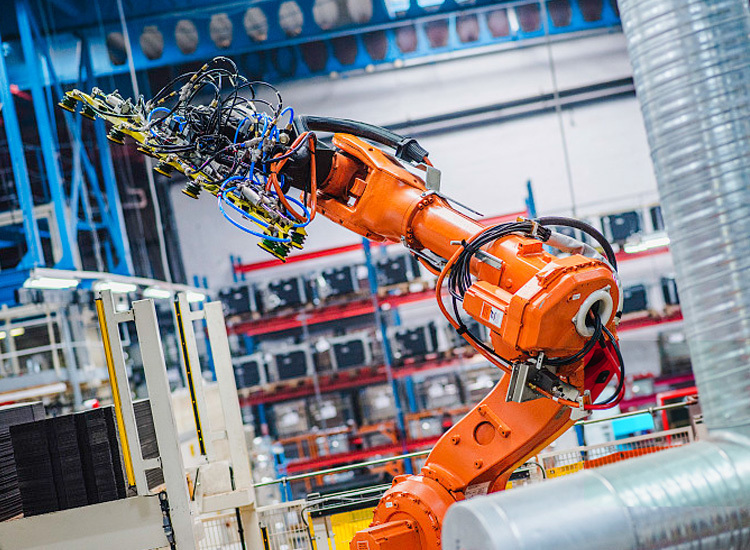

We work closely with our partners to fully understand their needs and leverage our innovative research and development of high-precision molds.

There are more than 70 100g -3000g Haitian injection molding machines, Japan's Yasuda Processing Center, Western Cut Wire Cutting Machine (Japan), and Chamil Precision Discharge Spark Machine (Switzerland)

02. R&D

The company has more than 300 employees, including more than 150 technical backbones, bringing together various expertise in management and technical backbones, and strictly controlling quality management and system management.

The company has passed the Rhine (TUV)ISO 9001 quality management system certification, ISO 45001 occupational health and safety management system certification, ISO 14001 environmental management system certification

News